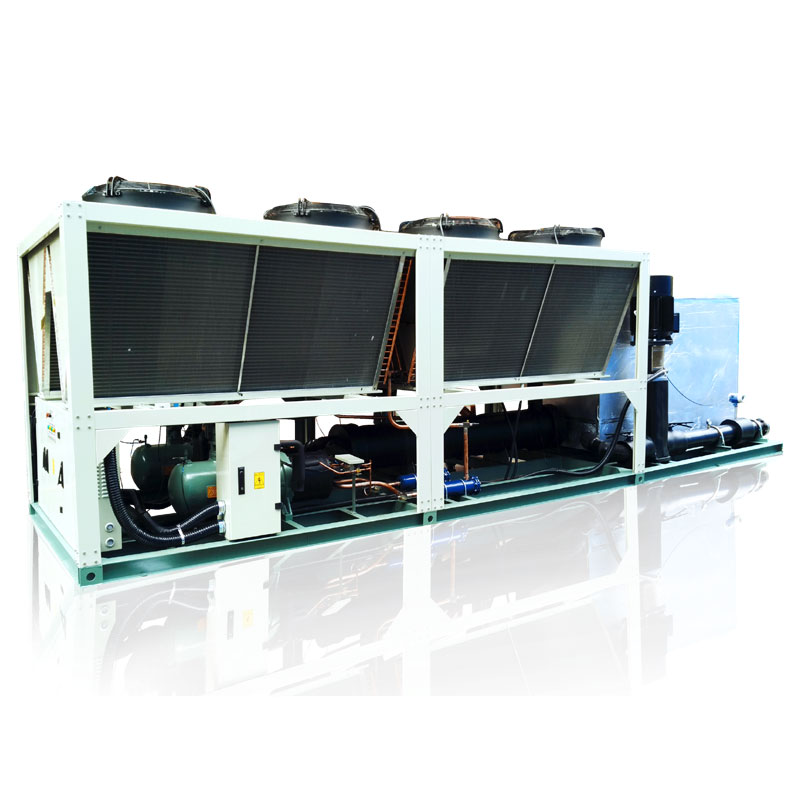

Heating Recovery Unit, Industrial Integrated All In One Chiller

1. Industrial chiller ① provide chilled water to the production line to keep required temperature for the processing line.

2. Industrial chiller ① while providing chilled water, through heat recovery with ② recover the heat from the compressor to produce hot water and preserve in the circulating water tank ③ then supply to the users ④ free all year around.

Note: This system provides free hot water to users, but hot water supply will depend on the chiller usage and the production line status, when the user uses this system, another hot water auxiliary system should be installed for back up.

In the transitional season and winter, the outdoor ambient temperature is lower than the process water temperature. Using outside cold air to cool down process water temperature without a turned-on compressor to achieve the most energy saving during transitional season and winter.

While ambient temperature below the process water, the process water is drawn into the heat exchange tubes and flowing inside the winter economizer. The equipped fan controls the flow of outside cold air to cool the process water to ensure the process water at its set temperature, which fulfills the cooling request and also saves 90% energy.

Heating Recovery Unit, Industrial Integrated All In One Chiller

1. Industrial chiller ① provide chilled water to the production line to keep required temperature for the processing line.

2. Industrial chiller ① while providing chilled water, through heat recovery with ② recover the heat from the compressor to produce hot water and preserve in the circulating water tank ③ then supply to the users ④ free all year around.

Note: This system provides free hot water to users, but hot water supply will depend on the chiller usage and the production line status, when the user uses this system, another hot water auxiliary system should be installed for back up.

In the transitional season and winter, the outdoor ambient temperature is lower than the process water temperature. Using outside cold air to cool down process water temperature without a turned-on compressor to achieve the most energy saving during transitional season and winter.

While ambient temperature below the process water, the process water is drawn into the heat exchange tubes and flowing inside the winter economizer. The equipped fan controls the flow of outside cold air to cool the process water to ensure the process water at its set temperature, which fulfills the cooling request and also saves 90% energy.

Heating Recovery Unit, Industrial Integrated All In One Chiller

1. Industrial chiller ① provide chilled water to the production line to keep required temperature for the processing line.

2. Industrial chiller ① while providing chilled water, through heat recovery with ② recover the heat from the compressor to produce hot water and preserve in the circulating water tank ③ then supply to the users ④ free all year around.

Note: This system provides free hot water to users, but hot water supply will depend on the chiller usage and the production line status, when the user uses this system, another hot water auxiliary system should be installed for back up.

In the transitional season and winter, the outdoor ambient temperature is lower than the process water temperature. Using outside cold air to cool down process water temperature without a turned-on compressor to achieve the most energy saving during transitional season and winter.

While ambient temperature below the process water, the process water is drawn into the heat exchange tubes and flowing inside the winter economizer. The equipped fan controls the flow of outside cold air to cool the process water to ensure the process water at its set temperature, which fulfills the cooling request and also saves 90% energy.

Heating Recovery Unit, Industrial Integrated All In One Chiller

1. Industrial chiller ① provide chilled water to the production line to keep required temperature for the processing line.

2. Industrial chiller ① while providing chilled water, through heat recovery with ② recover the heat from the compressor to produce hot water and preserve in the circulating water tank ③ then supply to the users ④ free all year around.

Note: This system provides free hot water to users, but hot water supply will depend on the chiller usage and the production line status, when the user uses this system, another hot water auxiliary system should be installed for back up.

In the transitional season and winter, the outdoor ambient temperature is lower than the process water temperature. Using outside cold air to cool down process water temperature without a turned-on compressor to achieve the most energy saving during transitional season and winter.

While ambient temperature below the process water, the process water is drawn into the heat exchange tubes and flowing inside the winter economizer. The equipped fan controls the flow of outside cold air to cool the process water to ensure the process water at its set temperature, which fulfills the cooling request and also saves 90% energy.